|

| January 15, 2019 | Volume 15 Issue 02 |

Materials News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Weird stuff: Moon dust simulant for 3D printing

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Learn more.

Make nylon 3D-printed prototypes and parts in the office

The new SLS 300 from 3D Systems is an affordable, turnkey, closed-loop 3D-printing system designed to operate in a smaller-footprint environment. SLS 300 makes selective laser sintering available to a broader range of customers with a high-reliability, affordable solution to produce end-use parts. Users can produce tough, durable parts from a range of production-grade nylon materials. Amazing fill, finishing, and clean-up systems.

The new SLS 300 from 3D Systems is an affordable, turnkey, closed-loop 3D-printing system designed to operate in a smaller-footprint environment. SLS 300 makes selective laser sintering available to a broader range of customers with a high-reliability, affordable solution to produce end-use parts. Users can produce tough, durable parts from a range of production-grade nylon materials. Amazing fill, finishing, and clean-up systems.

Learn more.

Will it erode? 3D-printing materials comparison from Xometry

Which 3D-printed plastics are the toughest? In this "Will it ..." video, Greg Paulsen, Xometry's Director of Application Engineering, 3D printed Benchies (3D test models) using different materials (such as polycarbonate, PLA, polypropylene, ULTEM, and Nylon 11 and 12) and processes (such as FDM, SLS, MJF, SLA, LSPc, Polyjet, and DLS) and then ran several abrasion tests on them. Watch to find out which 3D-printed plastic is truly the toughest of them all!

Which 3D-printed plastics are the toughest? In this "Will it ..." video, Greg Paulsen, Xometry's Director of Application Engineering, 3D printed Benchies (3D test models) using different materials (such as polycarbonate, PLA, polypropylene, ULTEM, and Nylon 11 and 12) and processes (such as FDM, SLS, MJF, SLA, LSPc, Polyjet, and DLS) and then ran several abrasion tests on them. Watch to find out which 3D-printed plastic is truly the toughest of them all!

View Part 1.

View Part 2.

Graphene Handbook: Learn all about this wonder material

Metalgrass LTD has published the 11th edition of its "Graphene Handbook," a comprehensive resource on graphene technology, the industry, and the market for this wonder material made of single layers of atoms of pure carbon. The book includes development history, production methods, current research, an intro to metrology and standardization, and even an investment guide. Under 100 bucks for digital edition. Hard copy available too.

Metalgrass LTD has published the 11th edition of its "Graphene Handbook," a comprehensive resource on graphene technology, the industry, and the market for this wonder material made of single layers of atoms of pure carbon. The book includes development history, production methods, current research, an intro to metrology and standardization, and even an investment guide. Under 100 bucks for digital edition. Hard copy available too.

Learn more.

Who knew? How colorants affect plastic

In plastic injection molding, one aspect of polymer characteristics that doesn't always get the consideration it deserves is the addition of colorant. Believe it or not, there is a whole scientific body of knowledge about the ways in which adding color to plastic can affect its behavioral properties. This short article by Denny Scher of ICO Mold takes a high-level look at some of the different, and surprising, ways colorants can affect plastics.

In plastic injection molding, one aspect of polymer characteristics that doesn't always get the consideration it deserves is the addition of colorant. Believe it or not, there is a whole scientific body of knowledge about the ways in which adding color to plastic can affect its behavioral properties. This short article by Denny Scher of ICO Mold takes a high-level look at some of the different, and surprising, ways colorants can affect plastics.

Read the full article.

Retaining magnets from JW Winco: Universal and clever

JW Winco has expanded its magnet line to support more applications with new materials, shapes, systems, and even raw magnets. Learn about their latest offerings, including retaining magnets designed for corrosive environments (GN 50.8), encapsulated magnets designed for sensitive or painted surfaces (GN 51.8), handle magnets (GN 53.3), and powerful magnets designed to handle challenging environs (GN 52.6).

JW Winco has expanded its magnet line to support more applications with new materials, shapes, systems, and even raw magnets. Learn about their latest offerings, including retaining magnets designed for corrosive environments (GN 50.8), encapsulated magnets designed for sensitive or painted surfaces (GN 51.8), handle magnets (GN 53.3), and powerful magnets designed to handle challenging environs (GN 52.6).

Learn more.

3D print tool steel with the ease of a plastic

The Virtual Foundry, a pioneer in advanced 3D-printing materials, is excited to announce the launch of their latest innovation: M300 Tool Steel Filamet™ (not a typo). This material answers the demand for FFF 3D-printable Tool Steel, delivering unparalleled strength and versatility. What sets this material apart is its seamless compatibility with various 3D printers, including Creality, Bambu Lab, Ultimaker, and more. The filament prints effortlessly, resembling the ease of working with PLA (plastic).

The Virtual Foundry, a pioneer in advanced 3D-printing materials, is excited to announce the launch of their latest innovation: M300 Tool Steel Filamet™ (not a typo). This material answers the demand for FFF 3D-printable Tool Steel, delivering unparalleled strength and versatility. What sets this material apart is its seamless compatibility with various 3D printers, including Creality, Bambu Lab, Ultimaker, and more. The filament prints effortlessly, resembling the ease of working with PLA (plastic).

Learn more.

Great Resources: Sheet metal design guide

If you're looking for a basic guide to sheet metal design, this one from Xometry will serve your needs well. Follow the design requirements and tolerances in this guide to ensure parts fall closer to design intent. This is the type of information you'll sock away and then refer to again and again.

If you're looking for a basic guide to sheet metal design, this one from Xometry will serve your needs well. Follow the design requirements and tolerances in this guide to ensure parts fall closer to design intent. This is the type of information you'll sock away and then refer to again and again.

Read the full article.

Particle foam perfectly distributed thanks to simulation with Ultrasim

BASF's Ultrasim simulation solution now includes Infinergy, an expanded thermoplastic polyurethane (E-TPU) that is used in a wide range of applications to make components with particle foam -- from bicycle tires to the soles on shoes. Identify and solve problems related to pneumatic filling when distributing particle foams in molds, even taking gravity and mold closing into consideration. Avoid those pesky air pockets.

BASF's Ultrasim simulation solution now includes Infinergy, an expanded thermoplastic polyurethane (E-TPU) that is used in a wide range of applications to make components with particle foam -- from bicycle tires to the soles on shoes. Identify and solve problems related to pneumatic filling when distributing particle foams in molds, even taking gravity and mold closing into consideration. Avoid those pesky air pockets.

Learn more.

Premium polymer DLP printer is half the price of its predecessor

Desktop Metal has just launched the ETEC Pro XL -- a premium polymer digital light processing (DLP) printer that enters the market at less than half the price as its predecessor. DLP is regarded by many as a superior polymer 3D-printing technology for speed, surface finish, and accuracy. Ideal for automotive and machine parts, aerospace components, housings, connectors, jigs and fixtures, short-run molds, and more.

Desktop Metal has just launched the ETEC Pro XL -- a premium polymer digital light processing (DLP) printer that enters the market at less than half the price as its predecessor. DLP is regarded by many as a superior polymer 3D-printing technology for speed, surface finish, and accuracy. Ideal for automotive and machine parts, aerospace components, housings, connectors, jigs and fixtures, short-run molds, and more.

Read the full article.

CNC machining case study: One-of-a-kind computer chassis

Learn how Josh Sniffen, the YouTuber behind the popular PC-building channel "Not From Concentrate," trusted Xometry to provide a wide range of manufacturing options, personalized Design for Manufacturing (DFM) feedback, and order management support for his latest creation: the HEXO ATX computer chassis. All in all, Sniffen procured parts using Xometry's CNC machining service, selective laser sintering 3D-printing service, and sheet metal cutting and fabrication services. A neat insider look at the process.

Learn how Josh Sniffen, the YouTuber behind the popular PC-building channel "Not From Concentrate," trusted Xometry to provide a wide range of manufacturing options, personalized Design for Manufacturing (DFM) feedback, and order management support for his latest creation: the HEXO ATX computer chassis. All in all, Sniffen procured parts using Xometry's CNC machining service, selective laser sintering 3D-printing service, and sheet metal cutting and fabrication services. A neat insider look at the process.

Read this Xometry case study.

Which parts should be 3D printed? AI combs through CAD files to find out

One of the biggest challenges in transitioning to additive manufacturing (AM) is the ability to identify which parts are best suited for the process quickly and easily. Learn how Danfoss, Stanley Engineered Fastening, and even the U.S. military have utilized advanced additive manufacturing software to automate the process, reducing material waste and energy costs, improving part reliability, decreasing lead times, as well as now having the ability to identify part consolidation opportunities through intelligent AM decision-making.

One of the biggest challenges in transitioning to additive manufacturing (AM) is the ability to identify which parts are best suited for the process quickly and easily. Learn how Danfoss, Stanley Engineered Fastening, and even the U.S. military have utilized advanced additive manufacturing software to automate the process, reducing material waste and energy costs, improving part reliability, decreasing lead times, as well as now having the ability to identify part consolidation opportunities through intelligent AM decision-making.

Read the full article.

9 key design tips for injection molding

Keep costs down and quality up all while optimizing your injection molded designs with these helpful tips from Xometry. Learn how to build better injection molded parts and products -- using draft angles, ribs and gussets, radii, fillets, and more -- and set expectations for the injection molding process. Good info here.

Keep costs down and quality up all while optimizing your injection molded designs with these helpful tips from Xometry. Learn how to build better injection molded parts and products -- using draft angles, ribs and gussets, radii, fillets, and more -- and set expectations for the injection molding process. Good info here.

View the video.

Metal additive manufacturing: Rocket turbopump design

Mixing undergraduate curiosity and real-world engagement, two students from Colorado University Boulder Aerospace Engineering Sciences program, Zachary Lesan and Patrick Watson, started an independent effort on turbopump design and manufacture that is a lesson in determination and industry collaboration. With lots of supplies and advice from industry heavy hitters including Velo3D, CFturbo, SpaceX, and many more, their project has reinforced significant points being made about next-generation rocketry.

Mixing undergraduate curiosity and real-world engagement, two students from Colorado University Boulder Aerospace Engineering Sciences program, Zachary Lesan and Patrick Watson, started an independent effort on turbopump design and manufacture that is a lesson in determination and industry collaboration. With lots of supplies and advice from industry heavy hitters including Velo3D, CFturbo, SpaceX, and many more, their project has reinforced significant points being made about next-generation rocketry.

Read the full article.

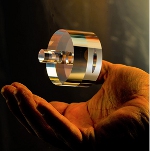

Transparent ceramics for extreme optics

Sapphire is an inherently transparent ceramic material that is resistant to extremes of temperature and environment. Sapphire can be processed to unique and precise shape/form by diamond grinding and polishing to allow full transparency. INSACO is a global leader in this capability -- and working with ultra-hard materials in general.

Sapphire is an inherently transparent ceramic material that is resistant to extremes of temperature and environment. Sapphire can be processed to unique and precise shape/form by diamond grinding and polishing to allow full transparency. INSACO is a global leader in this capability -- and working with ultra-hard materials in general.

Learn more.

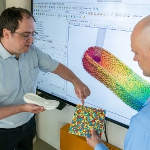

Hypersonic aircraft, lasers, and artificial intelligence: DARPA chief describes promising future defense technologies

Steven H. Walker, center, the director of the Defense Advanced Research Projects Agency, speaks with a reporter after a discussion with the Defense Writers' Group in Washington. Walker said the agency is being true to its roots in examining technologies and giving DoD options. [DoD photo by Jim Garamone]

By Jim Garamone, Department of Defense

The Defense Advanced Research Projects Agency (DARPA) will employ enhanced funding to discover technologies used to defend the homeland, bolster deterrence, and aid service members engaged in counterterror and counterinsurgency fights, the agency's director said on March 1.

Speaking with the Defense Writers' Group, Steven H. Walker said his agency is working on artificial intelligence projects, hypersonic technologies, promising biological technologies and advanced electronics, among other technologies.

"We understand we are in competition with countries like Russia and China," he said.

Competition with Russia, China

Russia and China are investing heavily in hypersonic technologies involving aircraft that travel between Mach 4 (about 3,070 mph) and Mach 8 (about 6,100 mph), and the two countries also worked on the capability to increase the range of their missiles and decrease the chance that they could be shot down.

DARPA, the U.S. Air Force, and NASA have been working together for years on the technology. At the beginning of the administration, Walker approached Defense leaders with the need for a national initiative to develop hypersonics.

"We did push for a comprehensive initiative in the budget process this fall," he said. "We did receive a budget increase at DARPA and some of the services to do more in hypersonics. I don't think we got all we wanted, but it was a good first step."

Walker looks forward to working with Mike Griffin, the new undersecretary of defense for research and engineering and former NASA administrator. "He understands this problem very well, and I've been told by Mike personally that this will be one of his top priorities," Walker said.

DARPA has supported experiments with hypersonic capabilities, and the boost in funding will allow the agency to assess what can be done with the systems, how effective they are, and how affordable they will be.

He expects test flights next year.

Laser technology

DARPA has also pushed the area of solid-state lasers being tested at White Sands Missile Range in New Mexico. Service members may use directed-energy weapons in a tactical environment soon. "These are not the size of a [Star Wars] light saber, but they can drive it around," Walker said.

In space systems, the agency is looking at the feasibility of very capable low-Earth-orbit satellites to handle a variety of needs from command and control to intelligence, surveillance and reconnaissance, to tactical warfighting.

"We've been talking about this for a while," Walker said. "The difference today is, the technology has moved along to allow you to think about having some pretty capable small satellites that you can put in at (low-Earth orbit) and in larger constellations. We are starting a program called Blackjack ... which is looking at how we leverage the commercial sector and what they want to do at [low-Earth orbit]."

This would be naturally resilient, because it would force an adversary to target a large number of satellites. They would be in low-Earth orbit and relatively cheap to place -- current satellites are in geosynchronous orbit more than 22,300 miles above the Earth.

Artificial intelligence

The director believes the United States is not falling behind Russia and China in artificial intelligence. AI has been on DARPA's plate since the 1960s, he said, and he makes a distinction between "autonomy at rest" and "autonomy in motion" when he discussed AI.

Autonomy at rest involves applications that use judgment to help humans make decisions or to search an area or to collate data.

Autonomy in motion deals with AI systems operating on their own, and while there is a place for these it stops short of the lethal-force decision. Walker said the United States will not allow a machine to make that judgment.

Walker says there needs to be more research in biological fields. He said DARPA is looking at developing flu vaccines in days rather than months or years. He wants the agency to look at ways to protect the nation from biological attack. He wants to look at the issue of gene editing that China, for example, is pushing ahead with. "Biology is a fast-paced field, and certainly you can see China is making a big investment in DNA sequencing and their DNA database," he said.

The United States also needs to invest in advanced electronics, Walker said. China is looking to bring all electronics manufacturing onshore.

"We're looking at the electronics resurgence initiative," he said. "This is $150 million to look at new designs and manufacturing techniques to bridge the gap between our global multinational companies in this country that are at the forefront of electronics in this country and the defense industrial base."

DARPA at its heart is a risk-taking organization, Walker said. World-class scientists are there for between three and five years and then move on.

"We get a lot of support from the White House, the Congress, the Pentagon -- apolitical support -- to do the right thing, to take risks," the director said. "They give us a lot of freedom to make decisions and to think differently and to start and stop our own programs. If you want an organization to produce out-of-the-box ideas and projects, to continue to disrupt the status quo and to question, then you want that organization to have some autonomy and flexibility."

Published March 2018

Rate this article

View our terms of use and privacy policy